Development of Catalysts for Fuel Cell Applications

Development of Catalysts for Fuel Cell Applications

Fuel cell catalysts represent a new business area which we, N.E. CHEMCAT CORPORATION, have been putting most emphasis on in recent years. Great expectations are on fuel cells, which utilize the reaction energy of hydrogen, as a clean next-generation energy source that does not emit CO2. Catalyst technology for accelerating the reaction for energy generation of hydrogen is essential to realize fuel cell technology.

Many countries including Japan have begun moving toward the goal of "virtually zero CO2 emissions by 2050". In particular, a movement to virtually ban sales of new gasoline-fueled vehicles, aiming towards a "hydrogen society" where hydrogen will be used as a main energy source, has become noticeably active.

In Japan, from 2019 to 2020, opportunities for sharing detailed issues with the aim of widespread use of fuel cell vehicles (FCV) using hydrogen were provided to the entire industry, mainly by the Ministry of Economy, Trade and Industry (METI), the New Energy and Industrial Technology Development Organization (NEDO), and the Fuel Cell Commercialization Conference of Japan (FCCJ). Further improvement of both activity and durability is required for electrode catalysts. To meet this demand, we will focus our efforts on improvement of the Pt catalyst and development of next-generation catalysts (Pt alloy and Pt core-shell catalysts).

History of development of our electrode catalysts for fuel cells

NECC: Development results for core-shell catalysts

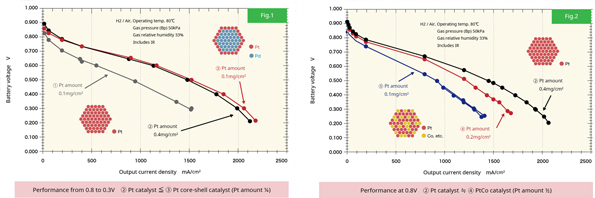

Performance of customer fuel cells equipped with NECC core-shell catalysts (Pt/Pd/C; 1st generation)

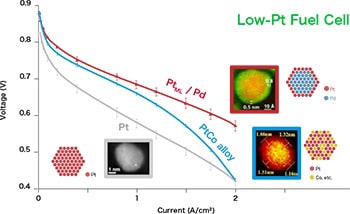

Excellent performance of NECC core-shell catalysts proven in MEA of FCV manufacturer

- Catalyst activity 4 times of Pt/C

- Fuel cell performance 4 times of Pt/C

- Pt usage amount 1/4 of Pt/C

- Fuel cell can be configured even with ultra-low Pt usage (for example 0.025mg/cm2)

- Higher output than Pt/C, PtCo/C in the overall current density region

- ※Particularly high performance observed in the high current density region.

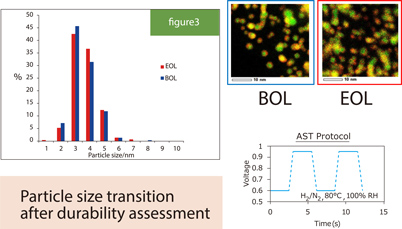

Advancement of mass-production technology

- NECC is improving the durability of core-shell catalysts and advancing mass-production technology.

- Addressing high performance with mass-production technology

- ※DOE MEA durability evaluation conditions(0.6-0.95V 30K cycle)

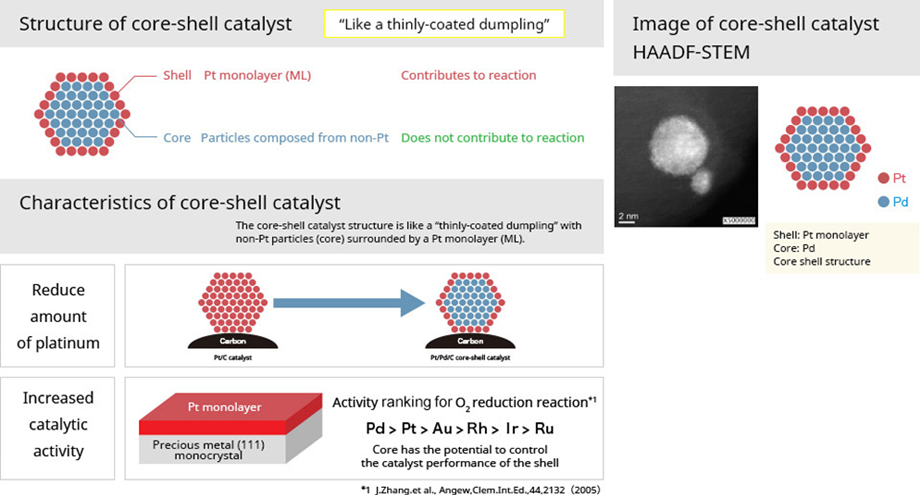

Basic structure and characteristics of core-shell catalysts