Development of Auto Exhaust Catalysts

Strengths of the Auto Exhaust Catalysts R&D

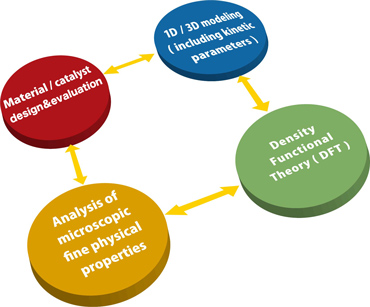

Based on the following perspectives, the Auto Exhaust Catalysts R&D Dept. engages in activities such as developing products, cultivating human resources, and cooperating with group companies/external organizations.

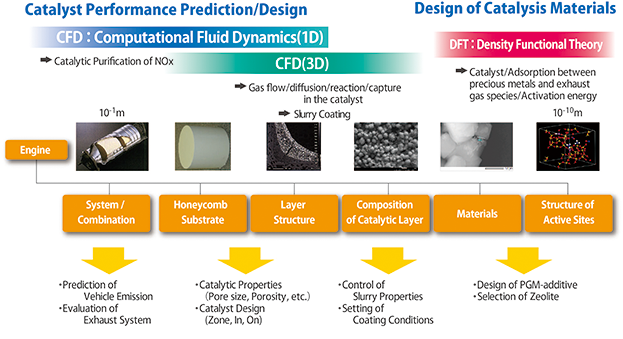

Development of materials/catalysts through a broad perspective from Åto m scale

Cooperation as the BASF Group

Global support

- We utilize the production and development centers of the BASF group to establish a global supply system.

- We periodically hold technical meetings with BASF.

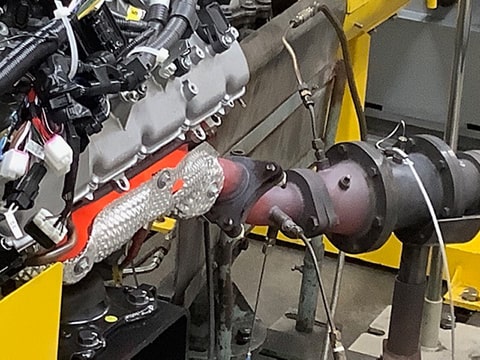

Engine Laboratory

- The Engine Laboratory uses actual engines and vehicles to test the durability and evaluate the performance of developed catalysts.

- Main experimental facilities are a dynamometer for controlling engine load and various analytical instruments for measuring emissions. In terms of both quality and quantity, the experimental facilities owned by our company are at the same level of our customers in automotive manufacturing. We constantly install the optimal facilities in response to regulatory changes and customer needs.

- Instead of simply conducting experiments, we constantly embrace challenges which include performing maintenance activities for keeping experimental facilities in optimal condition, thus ensuring the reliability of experimental data and increasing the efficiency of experiments through the effective use of equipment functions.

- Furthermore, from the perspective of safety, we strive to enhance features including interlock devices and surveillance systems, thus ensuring the safety of our employees.

-

Dynamometer for large engines

(also supports engines of 10 liters and greater) -

Gasoline durability

-

Chassis facilities

Engine Laboratory Facilities

[Gasoline engine test bench]

[Diesel engine test bench]

- SOx analyzer, NH3, N2O measuring device

- Micro tunnel (PM spectrometer)

- Equipment for measuring the solid particle number (PN spectrometer)

[Analysis Equipment]

- Downsize test equipment

(model gas testing machine) - Characterization equipment

- EPMA

- SEM/EDX

- STEM

- XRD

- TG/DTA

- Other analysis equipment

Numazu Engine Laboratory