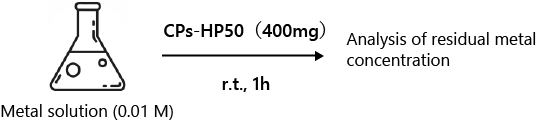

Scavengers, or absorbents, separate and remove metals contained in chemical compounds.

Scavengers in N.E. CHEMCAT‘s CPs series are powder-type metal scavengers that collect metals from precious-metal containing organic solutions. These scavengers can efficiently absorb and collect metals, leading to reduction of residual elements in processes such as pharmaceutical product manufacturing, high-purification in semiconductor manufacturing, and recycling of metals, a scarce resource.

Please contact our sales team for other product detail

Loss of the precious metal resources due to scrapping is considered as an important global challenge with the heightened awareness toward SDGs and the sustainable society. Among them, precious metals for catalysts are used in large amounts. However, as they contain a large quantity of impurities, recycling of precious metals requires advanced technological capabilities and know-how to operate the process.

Since its foundation, N.E. CHEMCAT has been in the precious metal collection business. Under the corporate philosophy of “We contribute to achieving a sustainable and quality global environment and affluent society through chemistry,” we consider precious metal recovery as a critical challenge from the sustainability perspective. Thus, we are committed to developing technology for recycling precious metals, which are scarce resources.

Sales Div., Business Development Dept