Strengthened regulations for nitrogen oxide (NOx), hydrocarbon (HC), carbon monoxide (CO), and particulate matter (PM) are planned on a global scale for on-road vehicles (passenger vehicles, buses, and trucks). Furthermore, acceleration in similar trends for strengthened regulations is also expected for off-road vehicles (construction machinery and agricultural machinery).

Strengthening of Exhaust Gas Regulations

Strengthening of Fuel Economy Regulations (CO2 emissions regulations)

In response to global warming, it is necessary to reduce the amount of CO2 emissions from automobiles. Improved fuel economy is becoming increasingly important as a measure for reducing emissions. Accordingly, strengthening of emissions regulations is planned.

Engines for Trucks, Buses, and Passenger Vehicles / Engines for Construction Machinery and Agricultural Machinery

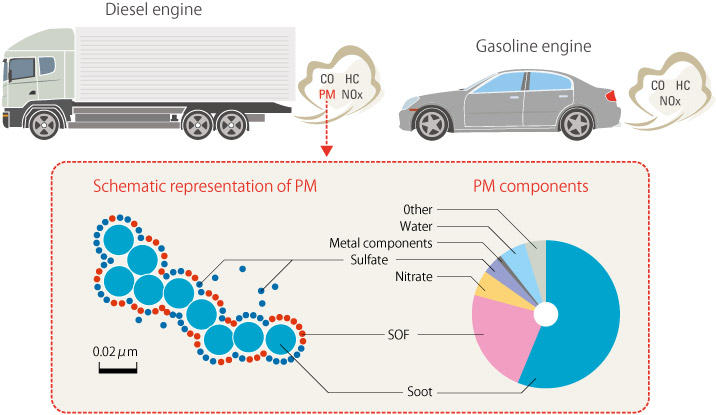

A major difference that sets diesel vehicles apart from gasoline vehicles is the emission of particulate matter (PM). Decreasing PM as much as possible is the most important issue that regulations and catalysts for diesel vehicles must address.

Nitrogen oxide (NOx), hydrocarbon (HC), carbon monoxide (CO), and particulate matter (PM) are hazardous substances contained in the exhaust gas of diesel vehicles. In order to reduce the emissions amount for these substances, catalysts such as DOC, CSF, SCR, and AMOX are combined and used.

Catalysts characteristics

| Type of catalysts | DOC Diesel Oxidation Catalyst |

CSF Catalyzed Soot Filter |

SCR Selective Catalytic Reduction |

AMOX Ammonia Oxidation catalyst |

|---|---|---|---|---|

| Function |

|

|

|

|

| Challenges |

|

|

|

|

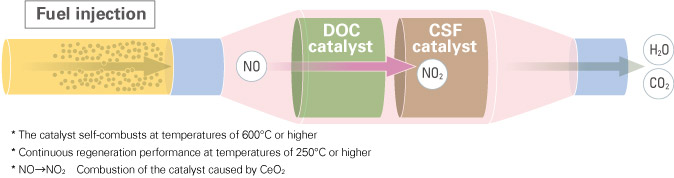

Combination of DOC Catalysts and CSF Catalysts to Prevent PM Emissions

We excel at developing and supplying DOC catalysts which are highly resistant to toxins such as S and low pressure loss CSF catalysts which utilize advanced coating technology.

During continuous regeneration

Role of DOC: detoxify CO into CO2, detoxify HC into CO2+H2O detoxification

By converting NO to NO2, supplies NO2 to CSF and promotes the burning of soot

Role of CSF: Trapped soot is burned by the catalyst

During forced regeneration

Role of DOC: Burns diesel which was flows from the previous process and supplies heat energy to CSF

Role of CSF: Forcefully burns soot at high temperatures; removes and regenerates soot which was trapped in the CSF

CO generated by incomplete combustion of soot is oxidized into CO2 and emitted

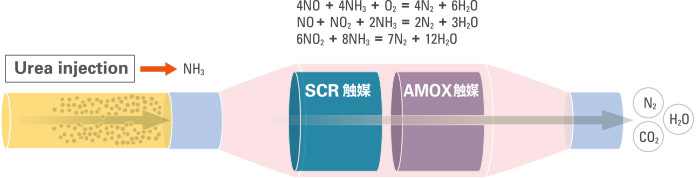

Combination Including SCR Catalysts and AMOX Catalysts in order to Meet Even Stricter Regulations (NOx reduction)

We excel at the development and supply of low pressure loss CSF catalysts that utilize advanced coating technology and selective catalytic reduction (SCR) catalysts which utilize high-performance zeolite and achieve high NOx removal performance.

Role of SCR catalysts: Adds urea (converts to NH3) to NOx (NO2, NO), which cannot be removed using DOC/CSF catalysts, and detoxifies it for emission by reducing it to N2 and H2O.

Role of AMOX catalysts: If NH3 slips from SCR catalysts, oxidizes the NH3 or detoxifies NOx for emission by reducing it through a reaction between NH3 and NOx.

Developing Next-generation Catalysts for High-performance and Compact Size

Our strengths include the development and supply of high-performance DOC catalysts which are made from small amounts of precious metal and SCR catalysts which match the needs of our customers' engines. We also excel at the development of high-performance SCR on Filters which matches the needs of our customers' engines.

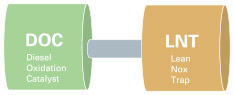

Our strengths include the development of lean NOx trap (LNT) catalysts which are ideal for compact and mid-sized engines, and the development and supply of low pressure loss CSF catalysts which utilize advanced coating technology. Furthermore, since these catalysts do not use urea, they offer increased convenience to users.